HyperSKU POD: 9 Popular Types of Shirt Printing Methods in 2025

Explore the 9 most popular shirt printing methods, including DTG, DTF, Screen Printing, Foam, Cracked, Vinyl, Mould Silicone, Embroidery, and Hybrid Styles. Learn the pros, cons, best uses, and how print-on-demand (POD) with HyperSKU makes launching your custom T-shirt line easy and risk-free.

HyperSKU

Posted on September 19, 2025

Thinking about starting your own T-shirt line in 2025? You’re not alone. Custom shirts are still one of the most popular products for online sellers, side hustlers, and even established brands.

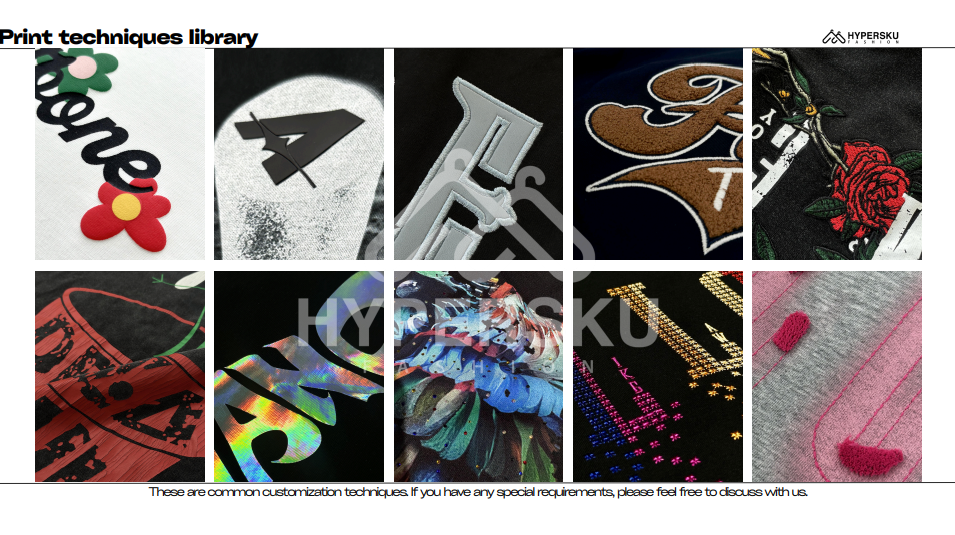

The tricky part is that there isn’t just one way to print a shirt—there are many. From classic screen printing to trending techniques like foam or cracked prints, each method comes with its own pros and cons.

In this guide, we’ll break down the 9 most popular shirt printing methods in 2025, show you what makes each one unique, and help you figure out which option fits your business best. And if you’re not sure where to start, don’t worry—we’ll also talk about how print-on-demand makes the process a whole lot easier.

Let’s dive in!

9 Popular T-shirt Printing Methods in 2025

When it comes to shirt printing, it’s hard to say which method is “the best.” Each one has its own look, feel, and cost structure. To help you sort it out, here’s a breakdown of the most popular options in 2025—along with the pros and cons of each.

Direct-to-Garment Print

Digital print is like having a giant inkjet printer for clothes. The machine sprays ink directly onto the fabric, making it possible to print super detailed graphics and full-color images without much setup.

- Pros:

- Perfect for small batches or one-off designs.

- Can handle complex artwork, gradients, and photos with ease.

- No setup costs—just load your design and print.

- Cons:

- Works best on cotton and struggles on polyester or blended fabrics.

- Slower and less cost-effective if you’re doing large bulk runs.

- Colors may fade faster than screen printing or embroidery.

Direct-to-Film (DTF) Print

DTF has become a star in 2025. Instead of printing directly onto the shirt, the design is first printed on a special film and then heat-pressed onto the garment. Think of it as DTG’s tougher cousin—it works on more fabrics and holds up better after washes.

- Pros:

- Incredibly durable—designs stay sharp after lots of washes.

- Works on different fabrics, not just cotton (like polyester and blends).

- More cost-efficient than DTG once you start scaling up orders.

- Cons:

- Slightly longer process since you print, then transfer.

- The finish can sometimes feel a little heavier on the shirt compared to DTG.

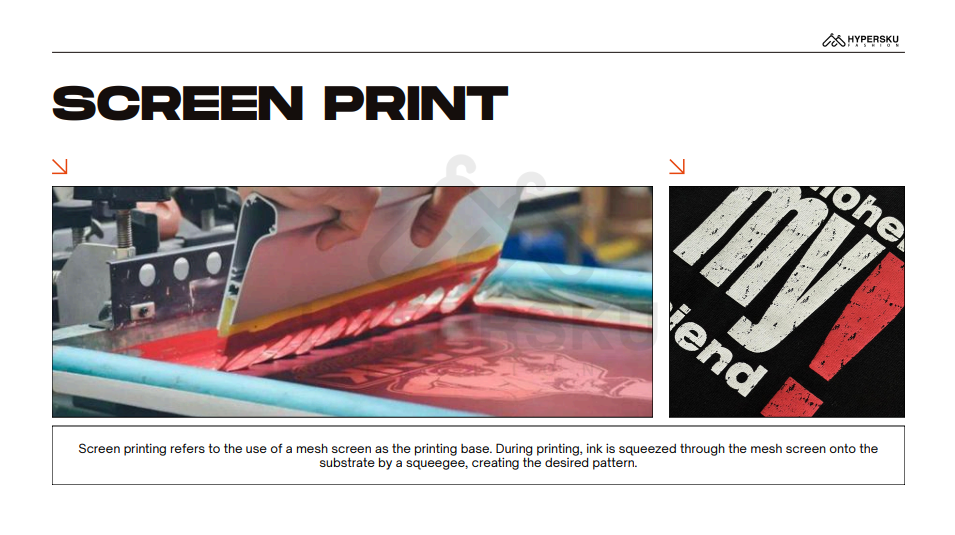

Screen Print

The old-school king of T-shirt printing. Screen printing pushes ink through a stencil (or “screen”) to build up bold, vibrant designs.

- Pros:

- Extremely durable—prints last for years without major fading.

- Colors stay bright and bold, even after repeated washes.

- Cost-effective for bulk runs (the more you print, the cheaper per shirt).

- Cons:

- Expensive setup for small batches.

- Not ideal for highly detailed or photo-like designs.

- Each new color requires a separate screen, which adds cost.

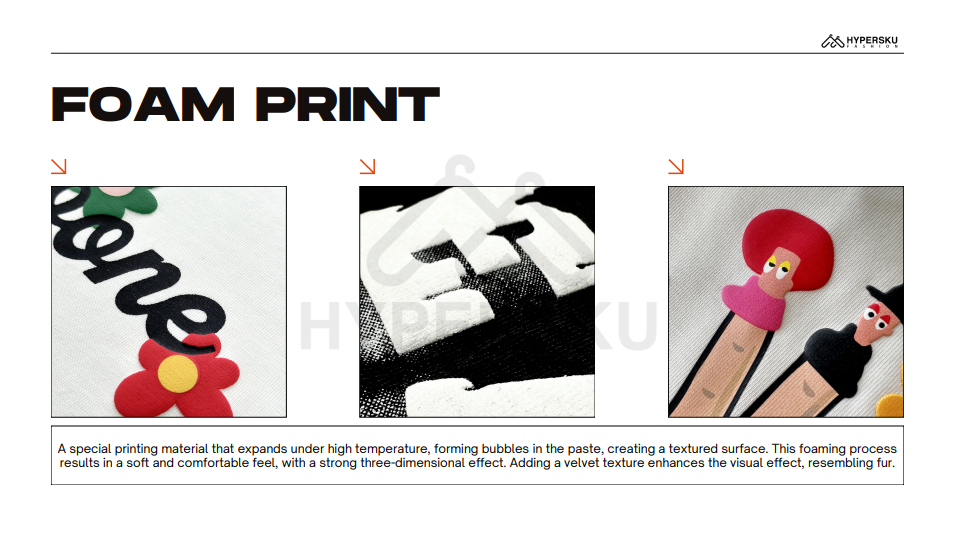

Foam Print

Foam printing uses puff ink that expands when heated, creating a raised, 3D look on the shirt. It’s especially popular in streetwear.

- Pros:

- Eye-catching 3D texture that makes designs pop.

- Works great for bold logos or statement graphics.

- Adds a fun tactile element to clothing.

- Cons:

- Not suited for fine details or intricate designs.

- Durability can suffer after many washes.

- Best used as an accent, not for full-shirt designs.

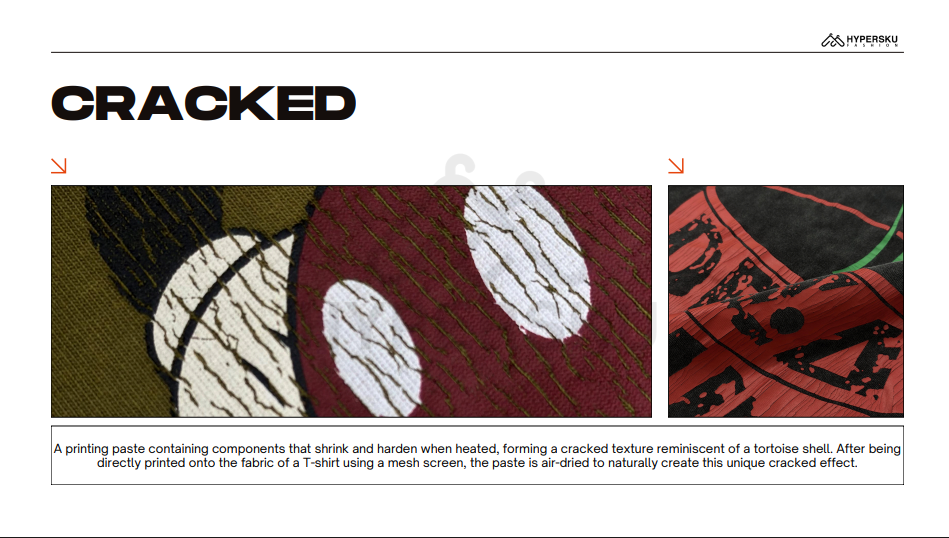

Cracked

This method gives your shirts that intentionally “worn-in” or vintage look—like a favorite band tee you’ve had for years.

- Pros:

- On-trend for retro and streetwear styles.

- Adds personality and character to otherwise simple designs.

- Works especially well for bold graphics or text.

- Cons:

- Limited flexibility—hard to apply to detailed artwork.

- Not everyone likes the distressed look.

- Can feel niche if your audience prefers clean finishes.

Vinyl

With vinyl printing, designs are cut from colored vinyl sheets and heat-pressed onto the shirt. It’s popular for sportswear and bold, simple graphics.

- Pros:

- Sharp, crisp finish that looks very clean.

- Extremely durable, especially for numbers and letters.

- Perfect for custom jerseys or uniforms.

- Cons:

- Not ideal for complex, multi-color designs.

- Can feel heavy and less breathable on larger designs.

- Limited texture options compared to print methods.

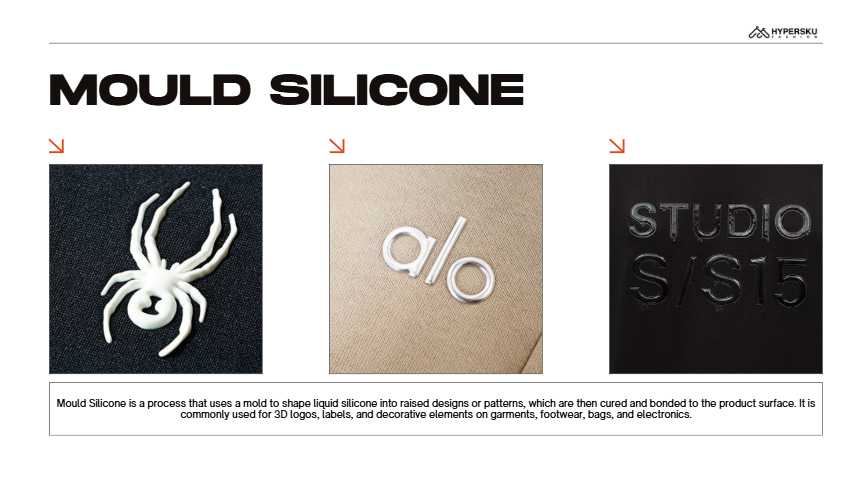

Mould Silicone

A premium technique that creates a thick, rubber-like layer on top of the fabric. It’s often seen in performance wear and luxury streetwear.

- Pros:

- Adds texture and depth—your design literally stands out.

- Highly durable and resistant to wear.

- Premium, high-end look that elevates your brand.

- Cons:

- More expensive than standard printing methods.

- Not suitable for thin or lightweight fabrics.

- Longer production process.

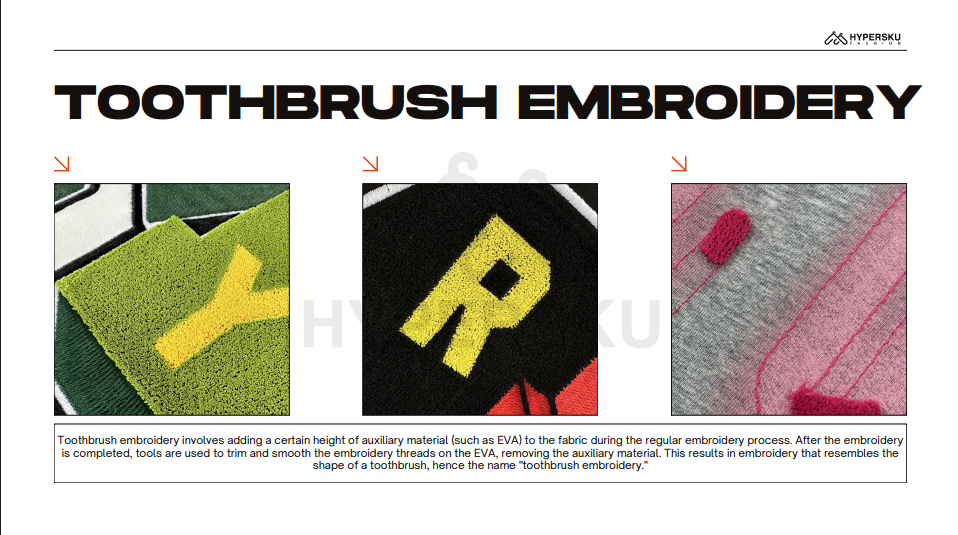

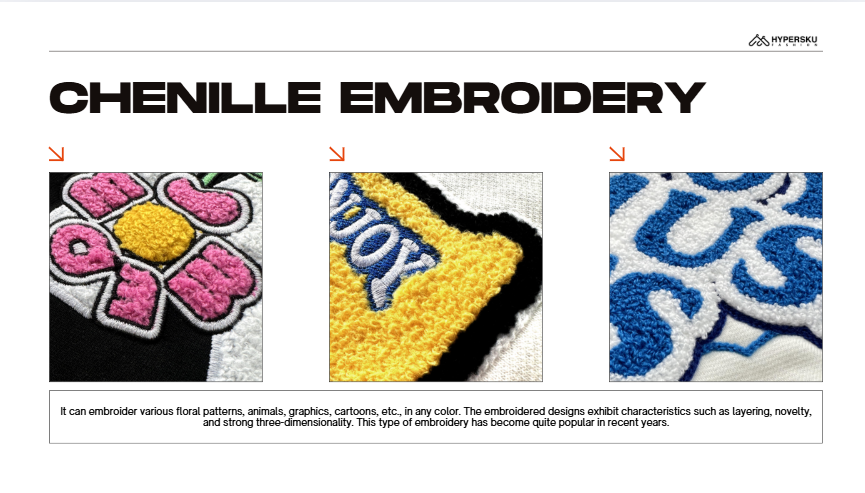

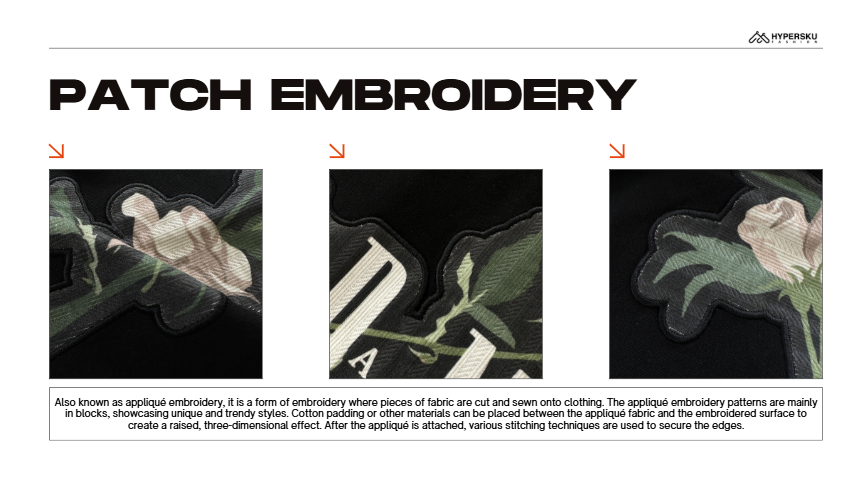

Embroidery (Toothbrush, Chenille, Patch)

Embroidery never goes out of style—it brings a premium, stitched finish to apparel. In 2025, we’re seeing creative variations:

- Toothbrush embroidery: sleek, smooth stitches for a neat look.

- Chenille embroidery: fluffy and bold, like varsity jackets.

- Patch embroidery: stitched badges that can be sewn or heat-pressed on.

- Pros:

- Premium, professional feel that boosts perceived value.

- Extremely durable—stitches last longer than most prints.

- Great for logos, branding, and statement pieces.

- Cons:

- More expensive and time-consuming than printing.

- Not suitable for large, full-shirt designs.

- Limited to simpler artwork (fine details get lost).

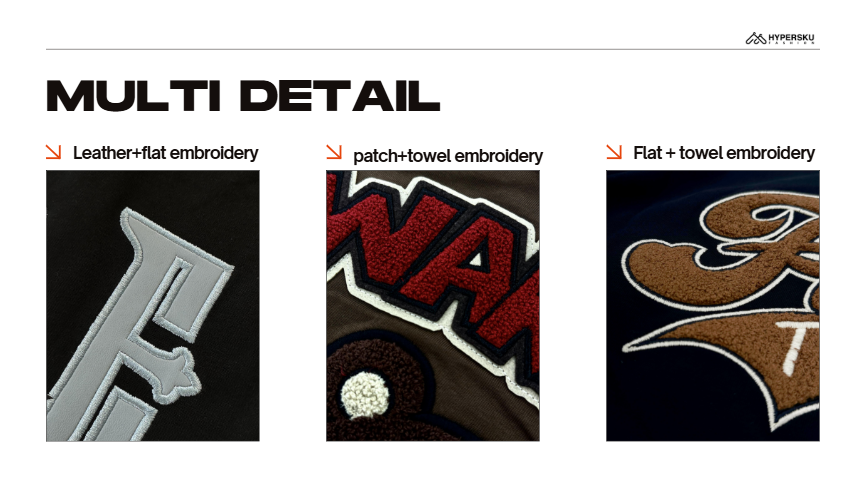

2.9 Hybrid & Niche Styles

Many brands now combine techniques—like screen printing with embroidered patches—to create layered, unique designs.

- Pros:

- One-of-a-kind look that helps your brand stand out.

- Appeals to fashion-forward buyers and niche markets.

- Lets you experiment with textures and styles.

- Cons:

- Higher production cost.

- More complex supply chain management.

- Not always scalable for large orders.

Which Shirt Printing Method Should You Choose

Choosing the right shirt printing method depends on your goals, budget, and who you’re selling to. A method that works well for a small local brand might not be the best fit for someone targeting streetwear fans or sports teams. In other cases, you may want a style that appeals to different customer groups. Here’s a simple way to compare the options side by side:

|

Printing Method |

Best For |

Cost Level |

Durability |

Fabric Compatibility |

Design Type |

|

DTG (Direct-to-Garment) |

Small batches, detailed designs |

Medium |

Good |

Works best on cotton |

Photographic, colorful prints |

|

DTF (Direct-to-Film) |

Versatile, various fabrics |

Medium |

Good |

Works on cotton, polyester, blends |

Full-color prints |

|

Screen Printing |

Large batches, bold designs |

Low per unit (bulk) |

Excellent |

Wide range |

Solid colors, simple graphics |

|

Vinyl Printing |

Custom names/numbers |

Medium |

Good |

Cotton, polyester, blends |

Letters, logos |

|

Embroidery (Standard, Chenille, Toothbrush, Patch) |

Premium look, textured style |

High |

Excellent |

Most fabrics |

Logos, brand names, patches |

|

Foam Print / Cracked Print |

Streetwear, trendy effects |

Medium |

Medium |

Cotton |

Textured, distressed designs |

|

Mould Silicone Print |

3D effects, luxury feel |

High |

Excellent |

Cotton, blends |

Raised, tactile designs |

Key Takeaways:

- Go with DTG or DTF if you want flexibility and colorful designs without bulk orders.

- Choose Screen Print for big batches and strong, long-lasting colors.

- Pick Embroidery or Silicone when aiming for a premium, high-value look.

- Use Foam or Cracked if you’re chasing streetwear or niche fashion vibes.

👉 If you’re still unsure, print-on-demand (POD) is a safe way to test different styles without upfront inventory costs—perfect for new brands or fast-moving sellers.

How Print-on-Demand Simplifies Shirt Printing in 2025

For many sellers, the hardest part of shirt printing isn’t picking the design—it’s managing inventory, dealing with minimum order quantities, and keeping up with fast-changing trends. That’s where print-on-demand (POD) comes in.

With POD, you don’t need to order 500 shirts upfront and hope they sell. Instead, every shirt is produced only after a customer places an order. This model makes it easier for new brands, small businesses, and even fast-scaling stores to experiment without taking big risks.

Here’s why POD stands out in 2025:

- No upfront inventory costs – launch new designs instantly.

- Test and adapt quickly – try out multiple printing methods (DTG, embroidery, silicone prints, etc.) without committing to bulk.

- Scalable – start small, then grow as demand increases.

- Low risk, high flexibility – perfect for sellers chasing seasonal or trend-driven markets.

🌟 Where HyperSKU fits in:

HyperSKU’s POD service is built for sellers who want to move fast without compromising on quality. You design the shirts, and we handle production, quality checks, and worldwide fulfillment. Whether you’re experimenting with DTG prints for a streetwear drop, embroidery for a premium collection, or silicone prints for a 3D effect, HyperSKU supports multiple methods under one roof. That means you can scale your business without juggling multiple suppliers or worrying about logistics.

We’ve already helped a brand grow from zero to steady five-figure monthly sales through POD—here’s one POD success story that shows what’s possible.

If you’d like to explore POD opportunities beyond t-shirts, check out our latest POD Whitepaper for deeper insights across multiple categories.

How to Start Your Own T-Shirt Line with HyperSKU POD

Starting a t-shirt line sounds like a huge project, but with POD it’s surprisingly straightforward. HyperSKU’s workflow is designed to take you from idea to finished product in just a few simple steps:

1.Pick your products – Browse HyperSKU’s catalog and choose the shirt styles you want to customize.

👉 Register and contact your dedicated HyperSKU agent to get access to the full catalog.

2.Choose your printing method – DTG, embroidery, silicone print, and more. Select the one that best fits your design and target audience.

3. Confirm your mockups – Decide on sizes, placement, and details. You’ll get clear previews so you know exactly how your shirts will look.

4.Order samples first – Before you launch, you can order samples to check quality and make any final tweaks.

Go live with your brand – Once everything looks good, your designs are ready for production and fulfillment. HyperSKU handles printing, packing, and shipping directly to your customers.

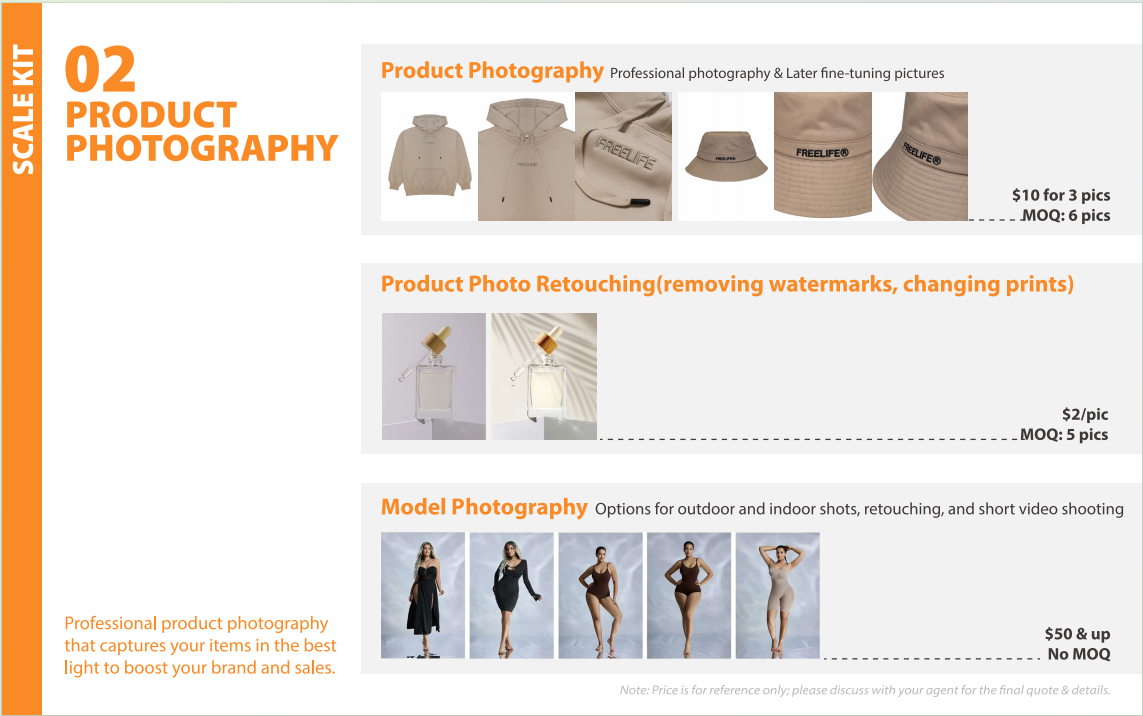

No design experience? No problem! You can start with blank styles and our print technique guide, and take your brand further with HyperSKU Brandlift Package, which provides label/packaging design and professional in-house product photography to make your t-shirts look polished and ready for market.

That’s it—you can go from concept to your own branded t-shirt line without worrying about factories, bulk orders, or logistics.

Final Thoughts

There are more options than ever for t-shirt printing—but with POD, you don’t have to overthink it. You can quickly test your designs, reach customers, and grow your brand without the usual hassle of factories or bulk orders.

Ready to launch your custom t-shirt business? 👉 Try HyperSKU POD Service now and start creating your branded t-shirts today.

Frequently Asked Questions About Shirt Printing Methods

1. Which T-shirt printing method is best for small batches or one-off designs?

For small runs or highly detailed designs, DTG (Direct-to-Garment) or DTF (Direct-to-Film) are ideal. They allow full-color prints without expensive setup costs. Using HyperSKU POD, you can test multiple designs without committing to bulk orders.

2. What printing methods work best for premium or textured looks?

Embroidery, mould silicone printing, and hybrid styles give a premium, tactile finish. These are perfect for logos, brand names, or luxury streetwear. HyperSKU can handle these methods through POD, so you can scale without managing multiple suppliers.

3. Can I start a T-shirt line if I have no design experience?

Absolutely! You can begin with blank styles and print technique guides. Plus, HyperSKU Brandlift Package offers label/packaging design and in-house product photography, making it easy to launch a professional-looking brand.

4. How do I choose the right printing method for my brand?

Consider your target audience, design complexity, fabric type, and order size. DTG/DTF are flexible for colorful prints and small batches, screen printing is cost-effective for bulk runs, and embroidery/silicone adds a premium touch. POD lets you experiment with multiple methods safely and affordably.

5. Do I need to worry about inventory or logistics?

Not at all. With HyperSKU POD, shirts are only produced after an order is placed. This eliminates upfront inventory costs, reduces risk, and simplifies fulfillment—so you can focus on design and marketing.